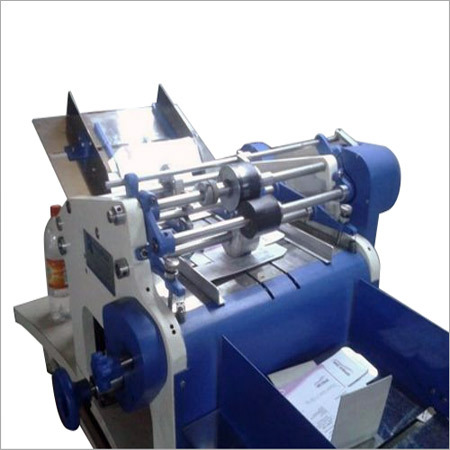

Winder Re-Winder Machine

Winder Re-Winder Machine Specification

- Usage

- Industrial

- Condition

- New

- Product Type

- Winder Re-Winder Machine

- Color

- Blue

- Warranty

- 1 Year

Winder Re-Winder Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 10 Days

About Winder Re-Winder Machine

Winder Re-Winder Machine:

We have designed this Winder Re-Winder Machine keeping in mind the required parameters of our clients. These Winder Re-Winder Machine perform the function of salvaging and rectifying printed and un-printed substrate after slitting. The Winder Re-Winder Machine is of cantilever construction, so that the loading of the parent reel and unloading of the rewound reel is both convenient and easy.

Both the rewind and unwind shafts are mechanically flexible & therefore, the core locking and unlocking can be achieved by, screwing and unscrewing a pair of nuts. Winder Re-Winder Machine is a pair of precision machine steel plates, braced together with tie rods and channel suction base, which forms the support structure of the machine.

We have specially designed our Winder Re-Winder Machine with unwind shaft and braking drums attached to the sliding plate which oscillates feeding on linear motion of the ball bearings.

The preferred braking torque on the unwind reel can be manually applied through a shoe brake requisite. Winder Re-Winder Machine is provided with a number of web support rollers that aids in smooth web flow before the rewind shaft. Our engineers have maneuvered the web in a manner that the sensor of the pneumo hydraulic edge guide can be conveniently altered as per requirement. We have availed AC DRIVE variable speed for smooth operation of the machine (with soft start) in the range 0-120 mtr/minute along with cantilever type roll loading and unloading system.. We also have the provision for Inkjet Printer to be mounted on this machine.

Some of the technical specifications of this Winder Re-Winder Machine are:

- Specialized Cantilever Unwinding Shaft of system for easy loading & unloading of Unwind Roll

- Pneumo-Hydraulic Edge Guide System with Pneumatic Sensor, Hydraulic Cylinder of stroke length.

- Cantilever Winding shaft of with specialized Mechanical Expander & Chrome Plated Check Nut systems for easy loading & unloading of Rewind Roll

- D. C./AC Drive with Constant Line Speed Feature

- Specialized Proximity Pulse Feedback with its mounting accessories to maintain Constant Line Speed Feedback

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Coding and Marking Machine Category

High Speed Label Carton Stacker

Price 68000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : High Speed Label Carton Stacker

Color : Blue

Warranty : 1 year

Condition : New

Carton Label coding Machine

Price 65000 INR / Pack

Minimum Order Quantity : 1 Number

Product Type : Carton Label coding Machine

Color : Blue & White

Warranty : 1 Year

Condition : New

Auto Carton Coder

Price 12000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Auto Carton Coder

Color : Blue

Warranty : 1 Year

Condition : New

Batch Coding Machine

Price 65000 INR / Case

Minimum Order Quantity : 1 Number

Product Type : Batch Coding Machine

Color : Blue & White

Warranty : 1 Year

Condition : New

Send Inquiry

Send Inquiry Send SMS

Send SMS